Fiber optic cable usually works as the bridge of two devices for both new cabling installations and upgrades, including backbone, horizontal, and even desktop applications. This is how it works, the conventional electrical data signals are converted into a modulated light beam, then transported via a very small diameter glass or plastic fiber to a receiver that converts the light back into electrical signals. The fiber optic links can provide much higher bandwidth and performances than copper links do, making it an ideal choice for many high rate systems that require the transfer of large, bandwidth-consuming data flies over long distance. However, there are several different types of cables available on the market. Here is what you should know about them.

Fiber Optic Cable Types

Usually fiber optic cables contain several fiber, a strong central strength member, and one or more metal sheaths for mechanical protection. According to different standard, there are different types of fiber optic cables just as listed below. Just find what you need to build and expand your structured cabling system.

- Loose-Tube vs. Tight-Buffered Fiber Optic Cable

Loose tube and tight buffered are the two types of fiber optic construction. Both contain some type of strengthening member, such as aramid yarn, stainless steel wire strands, or even gel-filled sleeves. But each is designed for very different environments.

Loose-tube cable is specifically designed for harsh outdoor environments. It protects the fiber core, cladding, and coating by enclosing everything within semi-rigid protective sleeves or tubes. Many loose-tube cables also have a water-resistant gel that surrounds the fiber. This gel helps protect them from moisture, which makes loose-tube cable great for harsh, high-humidity environments where water or condensation can be a problem. The gel-filled tubes can also expand and contract with temperature changes. But gel-filled loose-tube cable is not the best choice when cable needs to be routed around multiple bends, which is often true in indoor applications. Excess cable strain can force fibers to emerge from the gel.

Tight-buffered cable, in contrast, is optimized for indoor applications. It’s easier to install, as well, because there’s no messy gel to clean up and it doesn't require a fan-out kit for splicing or termination. You can install connectors directly to each fiber.

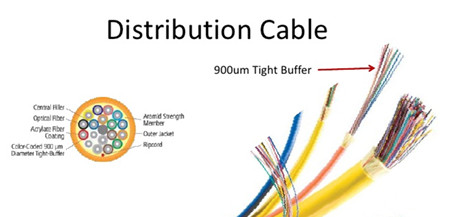

- Distribution vs. Breakout Cable

Distribution cables have several tight-buffered fiber bundled under the same jacket with Kevlar or fiberglass rod reinforcement. These cables are small in size and are used for short, dry conduit runs, in either riser or plenum applications. The fibers can be directly terminated, but because the fibers are not individually reinforced, these cables need to be broken out with a “breakout box” or terminated inside a patch panel or junction box.

Breakout cables or fanout cables are made of several simplex cables bundled together, making a strong design that is larger than distribution cables. Breakout cables are suitable for conduit runs and riser and plenum applications. Because each fiber is individually reinforced, these cables are easier to terminate, making breakout cable more economical over shorter distances. A OM1 LC-MTP breakout cable is shown in the below picture.

- PVC vs. Plenum-Rated

PVC cable (or riser-rated cable even though not all PVC cable is riser-rated), features an outer polyvinyl chloride jacket that gives of toxic fumes when it burns. It can be used for horizontal and vertical runs, but only if the building features a contained ventilation system. Plenum can replace riser, but riser cannot be used in plenum spaces. Note that riser-rated means that the jacket contains PVC. The cable carries a CMR (communications riser) rating and is not for use in plenums. The following image shows a SC fiber cable with the jacket material of PVC.

Plenum cable has a special coating, which doesn’t emit toxic fumes when it burns. A plenum is a space within the building designed for the movement of environmental air. In most office buildings, the space above the ceiling is used for the HVAC air return. If cable goes through that space, it must be plenum-rated.

- Interlocking Armored Cable

This fiber cable is jacketed in aluminum interlocking armored so it can be run just about anywhere in a building. Ideal for harsh environments, it is rugged and rodent resistant. No conduit is needed, so it’s a labor- and money-saving alternative to using Inner-ducts for fiber cable runs.

- Aerial Cable

Aerial cables are for outside installation on poles. They can be lashed to a messenger or another cable or have metal or aramid strength members to make them self supporting. The cable has a steel messenger for support. It must be grounded properly.

Summary

Fiber optic cables are very suitable in applications that need high bandwidth, long distances, and complete immunity to electrical interference. Besides the above fiber types, more types of cable are available such as single-mode and multimode, simplex and duplex, indoor/outdoor cable, etc. If you are looking for vendors that can supply the fiber optic cables with high quality and low price, FS.COM won’t let you down. We offer a full selections of fiber optic cables (e.g. LC-SC fiber cable, LC to ST fiber cable, LC to FC patch cord) to save your time and money. Also custom service is available.

评论

发表评论